<p><br> <span class="small">March 15, 2024</span></p>

Life science supply chain: A path to sustainability

<p><b>To achieve a more sustainable way of doing business at scale and speed, businesses will need to move more quickly in their life science supply chain sustainability endeavors, according to our recent research.</b></p>

<p>Life sciences businesses have a two-pronged concern when it comes to sustainability. On the one hand, the health consequences of degraded environmental factors—from biodiversity loss, to fresh water access, to carbon emissions—result in a greater propensity to require medical treatments. On the other, the life sciences industry itself has a surprisingly large environmental footprint.</p> <p><a href="https://theconversation.com/big-pharma-emits-more-greenhouse-gases-than-the-automotive-industry-115285" target="_blank">According to the <i>Journal for Cleaner Production</i></a>, for instance, the global pharmaceutical industry emits 55% more carbon than the automotive sector in terms of tons of CO2e emitted per million dollars of revenue.</p> <p>As in other industries, the bulk of the life sciences environmental footprint is tied to the supply chain—the Scope 3 emissions they don’t influence directly. Indeed, BASF, a company that provides raw materials to the pharmaceutical industry, <a href="https://themedicinemaker.com/manufacture/its-time-to-calculate-the-carbon-footprint-of-pharmaceutical-products" target="_blank">reports that</a> Scope 3 emissions typically constitute over 80% of the total CO2 emissions of a typical pharmaceutical company, with around 70% of these Scope 3 emissions stemming from purchased goods and services.</p> <p>So far, however, according to our recent research, life sciences companies have primarily focused their efforts on enhancing sustainability within their internal operational domains, which are considered Scope 2 emissions. Fully 41% of life sciences executives say they are focusing on their operations to a very large extent, compared with just 24% emphasizing their supply chains.</p> <p>We partnered with Oxford Economics on the global study of 3,000 senior executives, including 295 in the life sciences sector. (For the full study, see “<a href="https://www.cognizant.com/us/en/insights/insights-blog/sustainability-in-business-beyond-green-to-deeply-green-wf1518050" target="_blank">Deep Green: how data, technology and collaboration will drive the next phase of sustainability in business.</a>”)</p> <p>The study reveals the growing consensus among industry executives regarding the significance of addressing sustainability challenges. A clear majority (65%) consider environmental sustainability to be highly important in their business strategy. Nonetheless, an even greater percentage (71%) believe it will take until at least 2044 to achieve a net-zero carbon footprint, with some companies aiming for 2054.</p>

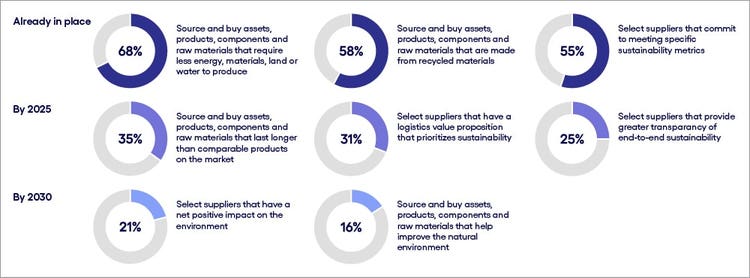

<h4><br> Emphasis on internal sustainability sets solid foundations for life science supply chain success</h4> <p>The good news is, the investments made in internal sustainability endeavors will serve as a strong foundation for Scope 3 work. Take, for instance, advancements in manufacturing facilitated by more efficient power generation or production technologies. Smarter manufacturing capabilities elevate equipment utilization rates, reducing raw material waste and optimizing the efficiency of every volt of electricity consumed.</p> <p>Further, the integration of digital technologies opens new avenues for driving efficiencies in alternative ways. Consider patient trials. Today’s industry leaders can deploy remote, digital and decentralized clinical modalities, diminishing the need for extensive travel to and from trial sites. In some cases, in-silico trials, where experimentation is performed entirely by computer, completely eliminate the human component, eradicating the necessity for physical visits to health facilities altogether. Additionally, remote patient monitoring solutions, such as wearables and telehealth, proves instrumental in mitigating the need for travel.</p> <p>Yet, beyond these innovations, life sciences leaders are shifting their efforts to their life science supply chains to varying degrees. For instance, AstraZeneca, through its "Ambition Zero Carbon" plan, aims to reduce greenhouse gas emissions from its global operations <a href="https://www.astrazeneca.com/sustainability/environmental-protection/ambition-zero-carbon.html" target="_blank" rel="noopener noreferrer">by an impressive 98% by 2026</a>. The multinational pharmaceuticals and biotech company says it is actively engaging with its entire value chain to measure and reduce Scope 3 emissions.</p> <p>Moreover, by the end of 2025, 95% of its spending in Scope 3 Categories 1 and 2 and 50% of spending in Scope 3 Categories 4 and 6 will be with companies that have science-based targets.</p> <p>Merck, another major pharmaceutical player, focuses on robust measures for Scope 1 and 2 emissions but adopts a more measured approach to Scope 3. The company’s goals include achieving climate neutrality by 2040, halving Scope 1 and 2 emissions and pledging to lower Scope 3 emissions by 52% per euro value-added. Similarly, Novartis plans to achieve carbon neutrality in Scope 1 and 2 by 2025 and across its life science supply chain by 2030.</p> <h4>Three waves of life science supply chain sustainability</h4> <p>In our study, we identified seven key activities that life sciences businesses should undertake to improve the environmental sustainability of their life science supply chains (see Figure 1). By analyzing the timeframes in which respondents plan to address these key areas, we can start to see a roadmap emerging for how organizations will work to reduce their Scope 3 environmental impacts.</p> <h4>Increased data intensity in supply chain sustainability endeavors</h4> <p><i>Q: When did you start, or do you plan to start, implementing the following initiatives relating to improving the environmental sustainability of your supply chain?</i></p>

#

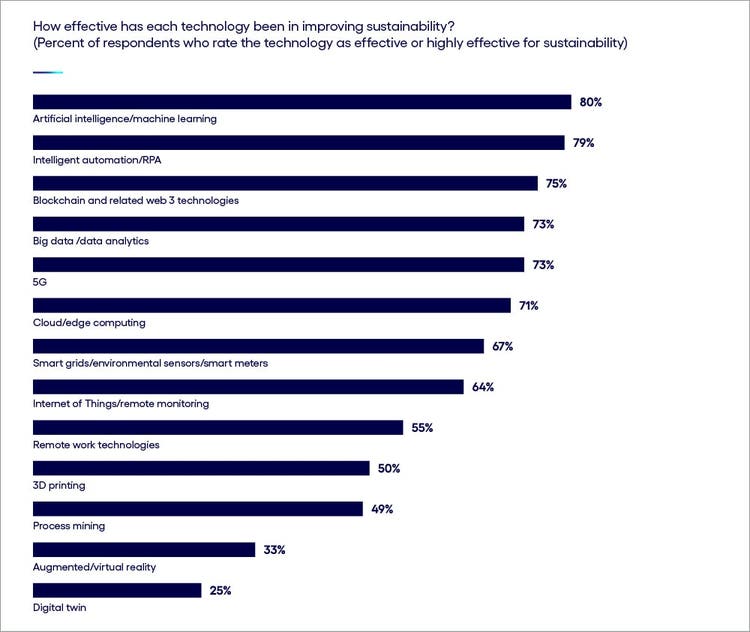

<p><span class="small">Base: 295 life sciences executives<br> Source: Cognizant and Oxford Economics<br> Figure 1</span></p> <ul> <li><b>Currently,</b> <b>more than half of respondents</b> have already begun sourcing materials that require fewer resources to produce or are made from recycled materials. They are also committed to selecting suppliers dedicated to meeting sustainability metrics.<br> <br> </li> <li><b>By 2025,</b> <b>companies will commit to more rigorous sourcing practices</b>, including placing a premium on supply chain partners that provide end-to-end transparency. In other words, life sciences companies will want to see what’s behind suppliers’ claims—the actual data-based evidence that shows how those metrics and conclusions were arrived at.<br> <br> To gain these insights, businesses will need new levels of cooperation and coordination with their supply chain partners, and new trusted and secure mechanisms, such as distributed ledgers (blockchain), for both sharing data-driven insights and metrics and modeling out possible scenarios.<br> <br> </li> <li><b>By 2030</b>, <b>life sciences businesses will explore sourcing and purchasing strategies</b> that not only have a low environmental impact but also help improve the natural environment. They will also seek suppliers that can prove they have a net positive impact on sustainability.<br> <br> This shift will see companies rely even more heavily on data as they strive for transparency. Indeed, in our <a href="https://www.cognizant.com/en\_us/insights/documents/deep-green-business-sustainability-wf1511601.pdf" target="_blank" rel="noopener noreferrer">Deep Green report</a>, we highlight how businesses plan to use more data sharing and increasingly sophisticated analytics to improve processes, create demand/supply simulations and build digital twins to more intelligently map their operations.<br> <br> But beyond the technology, the collaboration, transparency and information sharing involved will require new, disruptive ways of leading and operating that may change organization structures and even business models. For instance, forward-looking businesses might be open to atypical partnerships to help them reconceive products and services that they can develop, integrate and deploy to grow with sustainability.</li> </ul> <h4>Progress calls for bold action<b></b></h4> <p>To intensify efforts in life science supply chain sustainability, we propose the following actions:</p> <ol> <li><b>Assess the viability of actions across supply chains<br> </b><br> Life sciences organizations must confront significant challenges when working to enhance supply chain sustainability. Perhaps the greatest is the need to evaluate the economic and logistical viability of sustainability initiatives.<br> <br> For example, ambitious sustainability targets will come at a cost and potentially increase expenses throughout the life science supply chain. Such cost increases could impact the end-consumers of pharmaceutical products and medical devices, who may be unable or unwilling to bear the additional burden. Healthcare institutions are already grappling with financial stability issues, and raising prices could exacerbate these challenges.<br> <br> To address these complex and interconnected issues, companies should adopt a systems thinking approach that ensures sustainability initiatives benefit everyone across the ecosystem. Crucially, major life sciences companies are pivotal in aiding suppliers in achieving sustainability. For instance, in 2021, <a href="https://www.siemens-healthineers.com/press/releases/sustainability-2023" target="_blank" rel="noopener noreferrer">Siemens Healthcare partnered</a> with the University of California at San Francisco (UCSF) to enhance the sustainability of radiological imaging in northern California. This collaboration showcased both significant carbon reduction and cost savings in medical centers by employing practices like turning off or using the lowest power setting on MRI systems during idle hours.<br> <br> Overnight shutdowns, for instance, led to a 25% to 33% reduction in energy consumption. Utilizing power-save mode when the machine was switched off, a feature in newer Siemens Healthineers MRI scanners, further decreased power usage by 22% to 28%. It’s a win-win sustainable solution for the life science supply chain.<br> <br> </li> <li><b>Develop robust partner selection criteria<br> <br> </b>When overreliance on a partner is not an insurmountable systemic issue, companies should proactively define clear parameters for current and potential suppliers to follow. Leading organizations are moving beyond simple reporting and encouraging their suppliers to become equal stakeholders in their supply chains that actively contribute to environmental improvements.<br> <br> To achieve this, life sciences companies need to develop comprehensive plans for measuring and selecting providers based on a broader set of criteria than is currently employed. Pfizer, for example, <a href="https://www.pfizer.com/about/partners/B2B-and-suppliers/responsible-sourcing" target="_blank" rel="noopener noreferrer">has developed</a> a set of Supplier Conduct Principles that outline specific environmental requirements for potential partners. The company also works through established bodies such as the Pharmaceutical Supply Chain Initiative to ensure alignment with best practices.<br> <br> </li> <li><b>Foster collaboration across value chains<br> <br> </b>Life sciences companies should consider collaborative efforts to drive sustainability across value chains—including with competitors. Establishing partnerships and alliances with like-minded organizations can lead to shared best practices, pooled resources and collective influence on suppliers.<br> <br> Such collaboration can help mitigate the challenges posed by individual efforts and enable a more significant impact on sustainability. Yet, despite this clear area of opportunity, only 55% of life sciences organizations in our study are actively collaborating with their suppliers to improve their environmental sustainability.<br> <br> Recognizing this, GSK announced its <a href="https://www.gsk.com/en-gb/media/press-releases/gsk-launches-sustainable-procurement-programme-for-suppliers/" target="_blank" rel="noopener noreferrer">Sustainable Procurement Program</a>, which not only calls for suppliers to take action on sustainability commitments but also offers support in driving improvements. GSK will bring together 160 key suppliers to discuss how to work toward shared goals and learn what support suppliers need to get there.<br> <br> </li> <li><b>Embrace innovative technologies<br> <br> </b>The rapid advancement of technology offers opportunities to enhance supply chain sustainability. Investing in technologies such as blockchain, artificial intelligence and IoT can help life sciences companies identify areas for improvement, optimize resource usage and reduce emissions.<br> <br> Our study highlights the growing value enterprises will see from a diverse and evolving suite of technologies. For example, 80% of those who implemented AI to support sustainability initiatives believe the technology is adding value. Similarly, intelligent automation, blockchain, 5G, data analytics and cloud are proving effective for over 70% of respondents (see Figure 2).<br> <br> <a href="https://www.merckgroup.com/en/sustainability-report/2021/business-ethics/suppliers/supply-chain-management.html" target="_blank" rel="noopener noreferrer">Merck, for example</a>, has developed an automated carbon accounting tool to manage the large quantities of data on CO2 emissions from suppliers.</li> </ol> <h4>Sustainability tech effectiveness</h4>

#

<p><span class="small">Base: Varies, based on the share of respondents whose companies have used this technology to improve their environmental performance<br> Source: Cognizant and Oxford Economics<br> Figure 2</span></p> <h4>A sustainable future for the life science supply chain</h4> <p>As sustainability gains prominence in the business strategy of life sciences companies, it will become increasingly imperative to focus on life science supply chain sustainability. Armed with the right strategy and tools, life sciences executives can begin meeting their sustainability goals while improving how they work with partners throughout the value chain.</p> <p><i>Learn how your business (or you) can become sustainable to the core in our report, “</i><a href="https://www.cognizant.com/us/en/insights/insights-blog/sustainability-in-business-beyond-green-to-deeply-green-wf1518050" target="_blank" rel="noopener noreferrer"><i>Deep Green: How data, technology and collaboration will drive the next phase of sustainability in business.</i></a>”<br> </p>